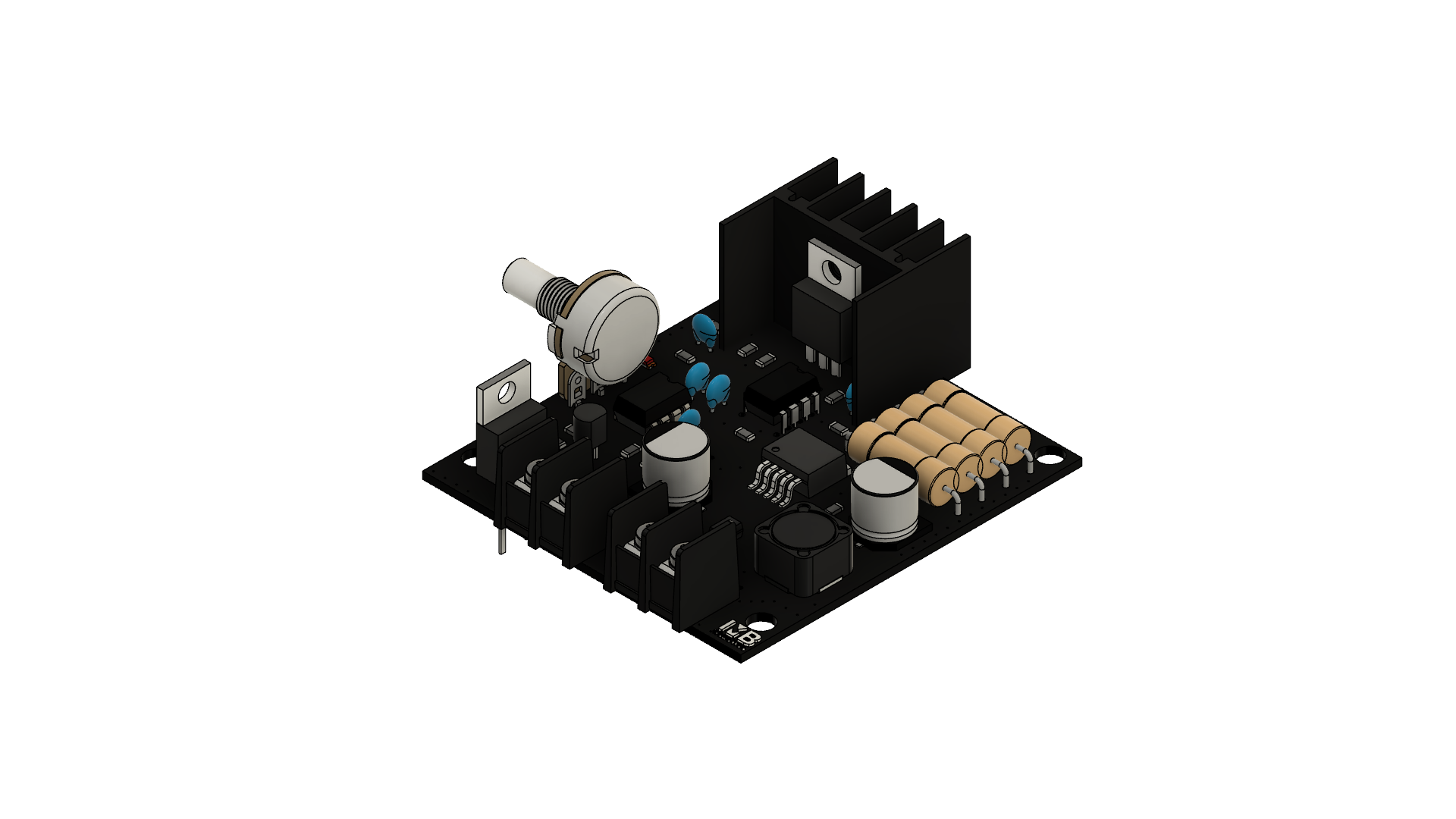

DYNAMIC BRAKE CHOPPER

Dynamic Brake chopper board, brake chopper 48 VDC 200 Watt is a brake chopper (also called shunt or regen board) that can be used with drivers with suitable inputs. It is used to consume excessive energy that may occur in the DC bus while the electric motor slows down the load.

Brake Chopper 48V 200W is capable of delivering up to 200W of continuous power if adequate cooling is provided.

When the motor is used to actively slow a load, electrical power will be regenerated. If the drives are supplied with a standard power supply (without recovery function), such regenerative duty points will cause an overvoltage in the DC circuit and therefore the drive or power supply will be turned off.

To prevent this from happening, a shunt circuit is required to burn this recovered energy.

Total shunt power required in a robotic system, robot inertia, payload, number of axes, size and type of motors, trajectory, controller settings, braking and fast stop strategies etc. It depends on many factors, including There is no universal rule to indicate how many IMB Brake boards are required for a given number of motors. Developers should calculate the regenerative forces and energies in the respective load cycle of their robot or measure these values in experiments.

For more detailed information about regenerative energy, then check out the blog post.

Technical Features

• Standard Bus Voltage: 48VDC

• Max. Voltage: 60 VDC

• Rated Continuous Power: 0-200W

• Max. Power: 200W (depending on cooling condition and duty cycle)

• Ambient temperature for power ratings: Room Temperature (20 °C)

• Max. System Temperature: < 75 °C